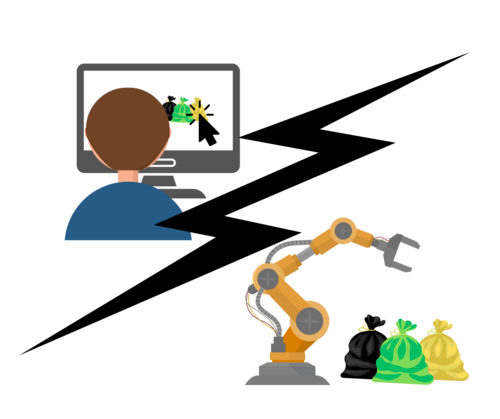

Collaboration of humans with robots and machines through Optimus

Human Assisted Vision (HAV) is a technology that combines the power of computer vision with the insights and expertise of human operators. HAV systems allow humans to work alongside advanced vision algorithms, providing input and guidance to improve the accuracy and efficiency of the system. Here are some key benefits of using HAV in your factory:

-

Enhanced accuracy: HAV systems allow humans to provide input to the vision system, increasing its accuracy and reducing the risk of false positives or false negatives. This results in more reliable and consistent results, which can improve the overall quality of your production process.

-

Improved problem-solving: Humans have a wealth of world knowledge and problem-solving skills that AI may not possess. HAV systems allow humans to use their expertise to solve complex problems and make accurate decisions, leading to better outcomes.

-

Better handling of complex visual data: In some cases, computers may struggle to accurately interpret visual data, particularly when dealing with complex or ambiguous images. HAV systems allow humans to provide context and guidance, improving the accuracy and reliability of the system.

-

Waste sorting: One example of the use of HAV in a factory setting is for waste sorting. HAV systems can be used to identify and sort general waste that cannot be recycled, reducing the amount of waste that goes to landfill and improving overall sustainability.

HAV is an excellent tool for enhancing the accuracy and efficiency in a factory setting. It allows humans to provide input and expertise to improve the system’s accuracy, solve complex problems, and handle complex visual data. Additionally, HAV can be used for a wide range of applications, from waste sorting to quality control, making them a versatile tool for a variety of industrial settings.

See our Case Studies for Human Assisted Vision

Demo Human Assisted Vision (HAV)