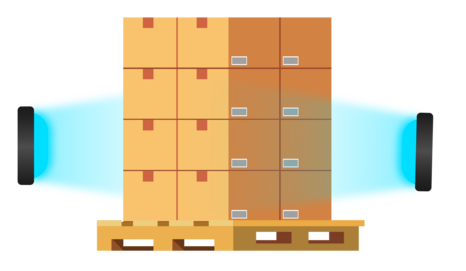

Optimus is an ideal tool for pallet inspection, as it offers a range of benefits, including:

-

Visual Inspection: Optimus can accurately identify any damage or defects on individual products or packaging, such as cracks, dents, or deformations. This helps to ensure that only high-quality products are being shipped and reduces the risk of damage during transportation.

-

Count Verification: The system can quickly and accurately count the number of products on the pallet and compare it to the expected quantity, ensuring that all items are accounted for and reducing the risk of missing items.

-

Quality Inspection: Optimus can identify any quality issues, such as contamination, foreign objects, or incorrect labeling, ensuring that only safe and high-quality products are being shipped.

-

Compliance Inspection: The system can check that the products and packaging meet relevant regulations and standards, such as barcode/QR readability or correct labeling, reducing the risk of non-compliance and associated penalties.

Optimus provides an effective and efficient way to inspect pallets, ensuring that only high-quality and compliant products are being shipped. Its visual inspection capabilities, count verification, quality inspection, and compliance inspection make it a versatile and valuable tool for any factory or warehouse that handles palletized products.

See our Case Studies for Pallet Inspection

Demo Object Fence